Stripped screws can be a nightmare to deal with, especially if you're in the middle of a project. Whether you're a DIY enthusiast or a professional, it's important to know how to handle a stripped screw. In this article, we'll discuss the different ways you can deal with a stripped screw to get your project back on track.

Identifying A Stripped Screw

The first step in dealing with a stripped screw is identifying it. A stripped screw is one that has lost its grip in the material it's screwed into. You can tell it's stripped if the screwdriver doesn't grip the screw head properly, and the screw keeps turning without coming out.

Using A Rubber Band

If the stripped screw head is visible, you can try using a rubber band to get a better grip. Place the rubber band over the screw head and press the screwdriver into it. The rubber band will fill the gaps in the screw head, providing more grip for the screwdriver.

Using Pliers

If the screw head is too damaged to use a screwdriver, you can try using pliers to turn the screw. Grip the screw head with a pair of pliers and turn it counterclockwise to remove it.

Using A Screw Extractor

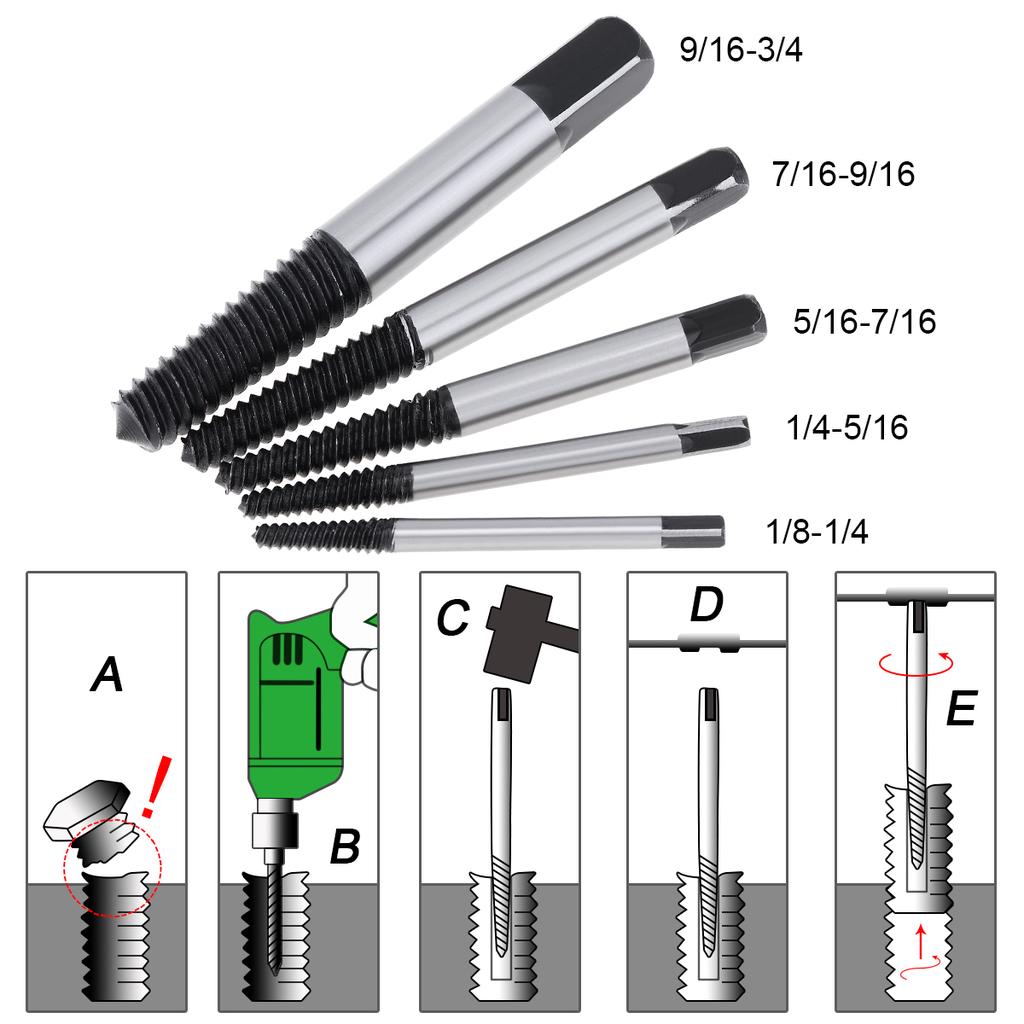

If the screw is completely stuck and won't come out, you can use a screw extractor to remove it. A screw extractor is a specialized tool that's designed to grip onto the stripped screw and turn it out. You'll need to drill a small hole into the center of the screw head and then insert the screw extractor into the hole. Turn the extractor counterclockwise to remove the screw.

Using A Dremel Tool

If none of the above methods work, you can try using a Dremel tool to cut a slot into the screw head. This will allow you to use a flathead screwdriver to remove the screw. Be careful not to cut too deep into the material surrounding the screw.

Preventing Stripped Screws

Prevention is always better than cure, and there are a few things you can do to prevent stripped screws. Firstly, make sure you're using the right size and type of screwdriver for the screw you're using. Secondly, apply pressure to the screw while turning it to prevent it from slipping. Finally, lubricate the screw with a little bit of oil or wax to make it easier to turn.

Conclusion

Dealing with a stripped screw can be frustrating, but with the right tools and techniques, it doesn't have to be. Whether you're using a rubber band, pliers, a screw extractor, or a Dremel tool, there's a solution to every problem. By taking steps to prevent stripped screws in the first place, you can save yourself time and hassle in the long run.